What is the observational method?

“With soil you are dealing with a material that is very variable over short distances, so any site investigation is only a snapshot of a data point”

Richard Ball, technical director, CGL

The observational method (OM) is an approach that enables a design to be changed during construction as a result of observations that are made about the way a material or structure is behaving. OM is often assumed to be a reactive process, to be used when unforeseen events occur, but it can also be used proactively to reduce overdesign and deliver projects more economically and efficiently.

The method gained widespread recognition when US soil mechanics expert Ralph Peck discussed it in his 1969 Rankine lecture Advantages and Limitations of the Observational Method in Applied Soil Mechanics. Peck argued that a lot of effort was going into the site investigations that informed geotechnical designs but that these investigations gave an incomplete picture of the actual conditions, so an engineer’s design would always be based on assumptions.

“Whenever you’re dealing with soil there is a lot of uncertainty,” confirms Richard Ball, technical director at geotechnical consultancy CGL. “You are dealing with a material that is very variable over short distances, so any site investigation is only a snapshot of a data point.”

Given this situation, designers tend to adopt one of two approaches: apply a high factor of safety, or make assumptions based on previous experience of similar conditions. Peck suggested that the first of these approaches was wasteful, while the second was dangerous. Instead, he advocated a third approach – the observational method – in which the design is changed during construction as more information is gained about the actual conditions.

How is the method used?

Guidance on the observational method is given in Eurocode 7: Geotechnical Design (EC7), and CIRIA’s Guidance on embedded retaining wall design (C760), which outlines different ways in which the approach can be used, both proactively and reactively.

The three main ways to use it proactively – i.e. as a planned method of achieving the best outcome, rather than in response to an unforeseen event – are:

- A) Start with an assumption that the conditions will be good but have a contingency design ready if the parameters change

- B) Start with a conservative design and have a contingency design ready if the conditions are better than planned

- C) Start with a design that everyone is comfortable with and update it constantly based on the observations of what is happening onsite

Option A

Following Peck’s original description of OM, the initial design is undertaken using the ‘most probable’ parameters for the soil and structure behaviour. Alongside this, a set of contingency measures is developed that would assure the stability of the structure if the behaviour tended towards ‘characteristic’. (The terms ‘characteristic’ and ‘most probable’ are defined in EC7.)

Depending on the observed behaviour, the construction either continues following the most probable behaviour or the pre-planned contingency measures are implemented. Peck saw the application of contingency measures as a risk mitigation. There are few recent examples of Option A because it is not normal practice to design walls based on most probable parameters.

Option B

This approach takes the opposite starting point to Option A, with the initial design based on the more conservative characteristic assumptions for the ground and the wall behaviour and an alternative construction sequence designed for the most probable behaviour. Depending on how observations develop, the design/construction team decides if it can implement the modifications in the most probable design. In this situation, the application of modification is an opportunity for cost and time savings.

Option C

Both Options A and B involve preparation of two separate designs and switching from one to the other if trigger levels are reached on a critical observation. C760 guidance identifies a third option (C) in which improvements are made to the construction sequence that have not previously been formally defined. In their 2020 book The Observational Method in Civil Engineering: Minimising Risk, Maximising Economy, Alan Powderham and Anthony O’Brien call this “progressive modification”.

Progressive modification

“OM designs must be carefully developed to suit each case and are consequently not served by a prescriptive approach”

Alan Powderham, former director of transportation, Mott MacDonald and Tony O’Brien, global practice leader for geotechnics, Mott MacDonald

If a progressive modification approach is adopted, the initial design can be based on any predefined parameters and there is no parallel design. Instead, the behaviour of the soil and structure are constantly reviewed during construction using critical observations that are fed back into the design model to update the initial parameters and re-run the predictions. This enables changes to be introduced sequentially at any time during construction, based on observational feedback, in contrast to the prescriptive approach of the previous two options, in which there are just two alternative designs.

There is no need to start construction with an unduly optimistic design or one that is based on estimations of the most probable conditions. Instead, the stakeholders on the project can agree an initial design that has a level of conservatism they are comfortable with.

For this to work, Powderham and O’Brien say it is essential to have a realistic appreciation of the potential conditions, from the most probable to the most unfavourable, based on site investigation and analysis, experience and engineering judgment: “Applications of the OM are not routine, and it can be very risky to treat them as such – even for apparently similar situations. OM designs must be carefully developed to suit each case and are consequently not served by a prescriptive approach,” they say.

Progressive modification is a flexible approach that maximises value by facilitating the introduction of beneficial design changes in a safe and controlled manner at any time. And if the OM starts from a demonstrably safe conservative base, most of the design changes are likely to be beneficial. It was adopted during construction of the western ticket hall for London's Tottenham Court Road station as part of the Crossrail project, saving four weeks of construction time and £715,000 in cost (see Case study 1).

Progressive modification is popular in the UK, while some other territories, such as Singapore, can tend to favour the more prescriptive approach, whereby an alternative design is prepared in advance of construction.

Benefits

There are numerous benefits to using the observational method, including:

- Cost savings

Using a design that is the best fit for the actual conditions rather than being overly conservative reduces unnecessary costs - Time savings

Taking out unnecessary construction activities may speed up the programme - Carbon savings

A reduction in materials and time spent onsite cuts carbon from energy and production - Increased safety during construction

OM can result in some below-ground activities being reduced or eliminated completely - More effective collaboration between clients and design/construction teams

OM requires all parties to agree a working methodology and share the benefits and risks - The industry learns from experience and improves future practice

Monitoring and observing the materials and structural works improves understanding throughout the profession - Stronger connection between design and construction

The OM approach involves the design being refined during the construction process, so the two are interlinked - Improved understanding of soil/structure interaction

Instrumentation and data analysis gives engineers direct feedback on how soils and structures behave

When should OM be used?

The OM approach can be used for any project provided the critical observations can be identified along with the means to obtain and act on them in a safe and timely manner. As Powderham and O’Brien say: “If it is not possible to change the design during construction, the OM is a non-starter.”

It can be used for both temporary and permanent works and is most effective when the critical observations can be obtained reliably through simple measurements.

The other essential factor is that all stakeholders must be committed to using the approach, which requires:

- A convincing business case

The benefits of adopting the observational method should be clearly established and communicated to stakeholders, and its advantages must be sufficiently convincing when evaluated against the established base design case or other potential alternatives. - A sound technical basis

Applications of the observational method inherently involve some form of soil/structure interaction. Both the geotechnical and the structural aspects must be appropriately assessed and understood, and OM practitioners need to have commitment, competence and clarity that is evident to stakeholders. - An understanding of risk management

Maintaining and demonstrating an acceptable level of safety is essential. OM practitioners require an active and broad appreciation of stakeholders’ perspectives on risks and constraints, including those relating to commercial programme and contractual issues. - Trust

Central to any application of the observational method are interpersonal relationships in which trust between the parties plays a key role.

Challenges

The main reasons why OM is not used more frequently are:

- A misplaced belief that it increases risk

- A desire for certainty at the start of a project

- Contractual conditions that inhibit design changes during construction

- A lack of equitable sharing of benefits and risks in the contract

Under a conventional contract, in which contractors bid on the basis of a fixed design, there is little scope for introducing OM. Bids are submitted on the basis that the project will be built as set out in the design, and any changes to the design during construction will present commercial risks that the contractor is unlikely to want to take on.

Design and Build (D&B) forms of contract offer greater potential to adopt OM, because design and construction are more closely interrelated and the contractor has significant ownership of the design. However, in practice, contractors are often under significant time pressures (especially during tendering) and it may be difficult to get the buy-in of the client, so it is easier for the D&B team to opt for a fixed design.

Contract forms that allow time to create a more collaborative environment and greater alignment of commercial interests, such as NEC4, Early Contractor Involvement (ECI) and Alliancing, offer more potential to use the Observational Method.

In NEC4, for example, there is a value-engineering (VE) clause for priced contracts (lump sum or bill of quantities) that sets out how savings can be shared between the client and contractor.

Powderham and O’Brien say that the optimum contractual environment for the method involves:

- Close coordination between the designer and contractor, allowing opportunities to be identified and developed

- A non-adversarial environment that facilitates teamwork

- Inclusion of a value-engineering clause so that benefits derived from the OM can be shared equitably between parties

- Trust between the client, designer and contractor and the fostering of longer-term relationships between them

The observational method in temporary works

The temporary works environment offers considerable opportunity for the OM because the contractor is responsible for both the design and construction and takes the commercial risk for what is done at this stage. As a result, they have an incentive to adopt techniques that will reduce time and costs.

“The most common application is for multi-propped retaining walls,” O’Brien says. The critical observations – such as the load going through the props and the deflection of the retaining walls – can be recorded easily, and props can be added quickly if the data shows they are needed.

“As well as time and programme benefits, there is also a safety benefit,” he says. “In a deep excavation where there are a lot of props there is risk associated with installing them, so if you don’t have to do that you are creating a safer environment.”

Technology – instrumentation and monitoring for OM

Tottenham Court Road station – western ticket hall

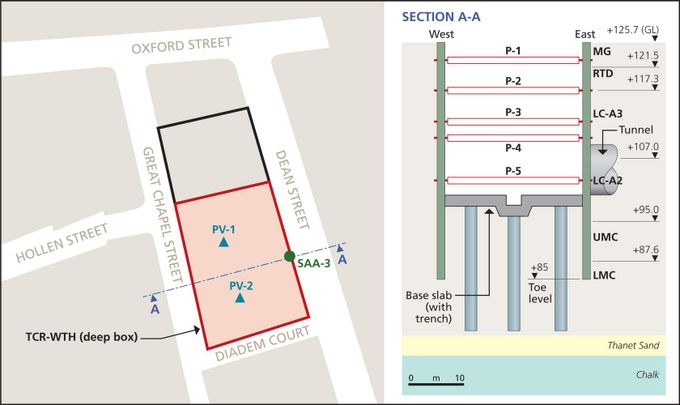

Instrument layout plan

Source: ICE Proceedings

Sensor and monitoring technology has advanced considerably in the past 50 years, enabling data to be collected very quickly – something that is essential in the application of OM. However, O’Brien says: “The OM is facilitated by the technology, but it’s not at the heart of the method. At the heart of it, you have got to have some engineers who truly understand the material.”

He says it is important to avoid installing excessive instrumentation because of the risk of data overload and because it might detract focus from the critical observations. In this, he echoes the words of OM pioneer Peck, who said: “Every instrument installed on a project should be selected and placed to assist in answering a specific question.”

Still, CGL’s Richard Ball says: “I think it’s worth monitoring everything because it gives you more information for future projects. That’s how we learn about how we can improve the design in the future.”

The progressive modification approach uses ‘back analysis’ – a methodology that feeds monitoring data back into the design models to provide a more accurate representation of the real soil behaviour. Advances in machine learning have made it possible to do real-time back analysis, so the design model can be updated as soon as the readings come in.

Case study: Tottenham Court Road station

Tottenham Court Road main construction site

In the UK, OM has been applied to several Crossrail deep excavations, including the head walls at Canary Wharf station, the Moorgate shaft at Liverpool Street station, the Durward Street shaft at Whitechapel station and the western ticket hall at Tottenham Court Road.

Before construction of the ticket hall at Tottenham Court Road, the contractor carried out a value-engineering study that identified the opportunity for an OM approach. This led to more comprehensive monitoring being installed and made it possible to modify the design at early stages through back analysis using inclinometer data.

By the third excavation stage, movements were less than predicted and the most probable soil design parameters had been calibrated through back analysis, enabling the lowest level of strutting (P5) to be omitted, resulting in four weeks of construction time being saved along with £715,000 in costs.

Tottenham Court Road station – western ticket hall

Temporary works and shaft construction

Case study: Subsea 7 HQ

Temporary works design for basement

Subsea 7 HQ, Sutton

Source: CGL

Description: A 14,000m2 HQ office for offshore engineering company Subsea 7

Contractor: Galliford Try

Geotechnical temporary works consultant: CGL

Challenge

Construction of the car park ramp for the new building had the potential to undermine the neighbouring Network Rail South West (NRSW) railway line. Other critical boundary constraints for the new basement included the need for temporary retaining works to provide working space and protect sensitive fuel storage tanks, trees, neighbouring buildings, and highway and sewer infrastructure.

Solution

CGL liaised with Network Rail and identified the need for specifically targeted supplementary site investigation, slope stability analysis, temporary works design and exemplary multi-hierarchy protocols for monitoring and trigger-level action and contingency planning.

Following successes using OM in chalk in buildings in Guildford and Dorchester, a pragmatic approach was adopted for a cost-saving combination of open-cut excavation and king posts with robust monitoring controls, rather than a contiguous pile wall.

The catalyst for these design changes was CGL’s supplementary site investigation around the basement perimeter and understanding of realistic geotechnical design parameters, hydrology and predicted ground movement modelling in structured chalk.

Outcome

The use of OM enabled the 5m-deep, 20,000m3 basement to be completed with only minimal temporary works on three sides and none at the Network Rail boundary.

Technology

CGL used ground-modelling software including WALLAP, GWALL, FLAC/Slope and PDISP to justify the proposed scheme and efficiencies in both the temporary and permanent works. Back analysis of the king post deflections showed that the props could be removed early ahead of constructing the ground-floor slab.

Subsea 7 basement. Source: CGL

Sign up to receive news from ICE Knowledge direct to your inbox.