Design risk management

The purpose of design risk management (DRM) is to eliminate or limit design-related uncertainty that can relate to cost, programme and buildability, or cause harm to people building and using structures, as well as others who may be affected.

Anyone involved in a construction project should understand their duties relating to DRM under the Construction Design and Management Regulations 2015.

It is easier and more cost-effective to tackle any problems during the design phase, when there’s time to develop a suitable solution, rather than addressing them in an unplanned way during construction or commissioning, or making changes once a structure is in use.

Every project should have a risk management strategy to anticipate and manage the risks that could occur as a result of hazards. DRM should be undertaken as an integral part of the overall project risk management process and as an iterative part of the design process, rather than as a bolt-on exercise.

What are hazards and risks?

The terms 'hazard' and 'risk' are often used interchangeably in the context of DRM, but they mean different things. A hazard is something with the potential to cause harm, while a risk is the likelihood of harm occurring based on exposure to the hazard.

Hazards and risks come in many forms. But, according to The management of design-related risks: structural civil and fire engineers by Collaborative Reporting for Safer Structures (CROSS), safety risk can be split into the following three broad types.

Non-codified hazards and risks generally originate during design. They are actions or omissions that don’t lead directly to a task onsite (or on the completed structure), but can create risks to others.

The danger with soft hazards is that, once a design leaves the design office, it’s unlikely that anyone onsite will spot them. There is therefore no ‘long-stop’ to catch them, whrereas there might be with a hard hazard such as working at height.

The causes of structural failure

Analysis of the main causes of structural failure shows that they fall into three categories, known as the 3Ps: people, process and product.

Most structural failures occur because of a shortfall in either people or process, or both, rather than a product failure. Examples of the soft hazards and risks associated with these elements of the 3Ps are summarised below.

Identifying hazards and risks

CROSS has produced guidance on how to approach hazard identification. It was initially developed for disproportionate collapse, but the advice is just as relevant to all risks associated with structural design.

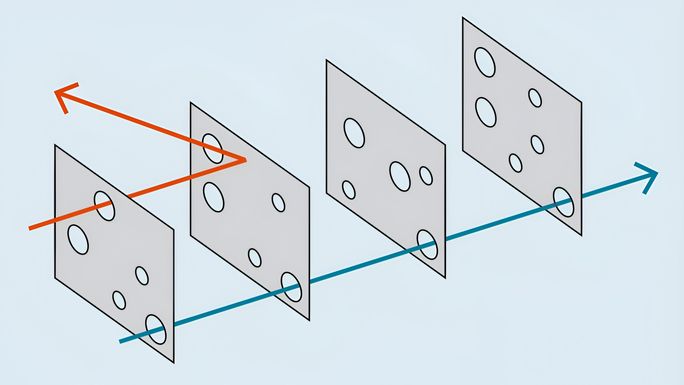

The guidance states that hazards are best identified by approaching the design from several angles. These are shown below.

Approaches to the successful identification of hazards

CROSS says: “Approaching the design from different angles is advantageous on the basis that several attempts to identify the hazards affecting the design are better than one. It will lead to repetition, but will also help to identify some hazards that had been missed through the earlier approaches.”

It is important that this approach is used to identify not only technical hazards – e.g. a car crashing into a column or a fatigue-induced failure – but also procedural failings (another term for soft hazards). These can be more important in the actual level of risk to which the design is exposed.

CROSS runs a secure and confidential safety reporting system that enables professionals across the construction industry to share their experiences to help others. Reports made by professionals about fire safety and structural safety issues related to buildings and other structures in the built environment are anonymised, reviewed by an expert panel and a legal team, then published. The aim is to create positive change and improve safety.

The following case studies, based on reports published by CROSS, show what can happen when soft hazards aren’t adequately managed to ensure safe design and construction.

Unsafe excavation practices

A routine inspection of a foundation excavation found that the builder had undermined the foundation of a masonry wall without being aware that the load of the building to which the wall belonged was now concentrated on a footing that was only two-thirds of its original width and the bearing capacity of the outer edge was almost zero, owing to the lack of lateral resistance.

The builder claimed to have always worked this way, showing a lack of awareness of the limitations of their knowledge. This case also demonstrates why civil and structural design engineers must clearly communicate site-specific hazards and design risks, such as the risk of undermining existing structures.

Soft hazards: Inadequate communication of design risks; Incorrect assumptions about capability; Reliance on methods that have worked before under different conditions.

CROSS safety report: Unsafe excavation practices

Dangerous retaining wall design

A design for a 1.8m-high brick retaining wall with a parapet on top, submitted for approval to a client’s technical acceptance authority, seemed to be too slender and the design was queried.

The designer said that a computer design package had been used, which showed a factor of safety of over two for overturning and sliding, and maintained that code checks were satisfactory. This did not seem credible.

Investigations showed that some parameters had been wrongly entered into the design program and dangerous assumptions had been made.

Soft hazards: Over-reliance on computer design packages; Inadequate experience of the designer undertaking calculations; Inadequate checking of the design (and sense-checking); Incorrect assumptions about structural fixings and the forces from them; A designer not being open to having their design challenged.

CROSS safety report: Dangerous design of a retaining wall

Understanding the construction method

A peer review of a design for a multi-storey reinforced-concrete flat slab frame, with a critical transfer slab at first-floor level, found that it hadn’t appropriately considered the frame’s construction sequence. The designer had undertaken their reinforcement design for the transfer slab using a ‘global’ or ‘whole building’ 3D design model that assumed the complete building structure was in situ and fully cured.

As a result, the loads on the transfer slab given in the analysis were much lower compared with a conventional ‘hand’ load take-down. The peer review indicated that several areas of the transfer slab were considerably under-reinforced, which could have led to the structural failure of an element and a possible disproportionate collapse.

Soft hazards: Designer’s inexperience; Lack of competent internal checking; Over-reliance on software; Assumptions about construction method not checked with contractor.

CROSS safety report: Concern over modelling of concrete frame building for construction stage

Weld de-specification

A steel fabricator was asked by a main contractor to de-specify full and partial penetration butt welds and replace these with 6mm-8mm fillet welds – without approval from the main design engineer – as a way to cut costs.

The fabricator asked for the drawings to be changed to match the changed description of the welds several times, but the contractor would not reissue the drawings while continuing to assure the fabricator that it was OK to proceed with the de-specification of the welds.

The fabricator eventually declined to continue with the project. They sought advice from the original designer, who said that, for structural reasons, the proposed changes to some of the welds should not be made.

Soft hazards: Changes to connection details and weld specifications not approved by the designer; Raising of health and safety concerns criticised rather than encouraged.

CROSS safety report: Weld de-specification without design approval

About CROSS

CROSS helps design and construction professionals to make structures safer by publishing safety information based on reports it receives and information in the public domain. Information is searchable on its websites by category, including structure type, location, risk, failure mechanism and material.

Engineers are urged to sign up for CROSS alerts and newsletters, and to report fire safety and structural safety issues, hazards and risks they encounter related to buildings and other structures in the built environment.

At present, CROSS operates in three regions:

Routine and non-routine activities

The process of identifying hazards can be simplified by differentiating between design decisions that result in well-known scenarios (‘standard’ or ‘routine’ activities) and those that need more thought and action (‘non-standard’ or ‘non-routine’ activities). If in doubt, activities should be classified as non-routine.

Routine activity: An activity that, using established contemporary practice, can be performed with accepted present-day levels of safety, health and wellbeing. These activities may be holistic in nature – that's to say a construction process that is made up of lots of individual tasks or activities – for example erecting a steel frame, laying drainage pipes or constructing a road pavement, rather than being broken down into individual tasks, providing none of these have any aspect that categorises them as ‘non-routine activities’. The designer should be aware that contemporary practice will change over time.

Non-routine activity: An activity for which contemporary practice does not exist, is unlikely to apply, or would be difficult to use or adapt. This includes routine activities that are subject to complicating factors preventing present-day levels of safety, health and wellbeing from being effective. Where feasible, discussions should include contractors (for construction tasks) and/or operators (for repair, maintenance or decommissioning tasks).

It is important to remember that routine activities can become non-routine if there are complicating factors. Examples are shown below.

Source: John Carpenter, Designing a Safer Built Environment: A Complete Guide to the Management of Design Risk

Managing risks during design

The questions in the below flow chart can help designers to decide the appropriate course of action for managing hazards and risks.

Source: John Carpenter, Designing a Safer Built Environment: A Complete Guide to the Management of Design Risk

Managing risks is as vital for soft hazards as it is for occupational safety and codified hazards, and can be achieved in the context of the 3Ps, as shown in the graphic below.

Source: John Carpenter, Designing a Safer Built Environment: A Complete Guide to the Management of Design Risk

Sign up to receive news from ICE Knowledge direct to your inbox.